Warehousing and logistics are critical components of the global supply chain, ensuring that products move efficiently from manufacturers to consumers. In these fast-paced environments, the reliance on mobile devices—such as handheld scanners, tablets, and RFID readers—is essential for daily operations. However, managing these devices effectively presents numerous challenges, from ensuring their availability and functionality to protecting them against loss, theft, and damage.

ARC’s intelligent lockers offer a comprehensive solution to these challenges, providing secure storage, real-time monitoring, and automated management of mobile devices. By integrating ARC’s technology, warehousing and logistics companies can optimize their operations, reduce device shrink, and enhance overall productivity.

The Challenges of Device Management in Warehousing and Logistics

High Volume of Device Usage

Warehousing and logistics environments are dynamic, with high volumes of goods and materials moving through facilities daily. Employees rely on mobile devices to scan barcodes, manage inventory, track shipments, and communicate across the supply chain. With hundreds of devices in use simultaneously, keeping track of each one can be a daunting task.

The continuous use of these devices also increases the likelihood of wear and tear, malfunctions, or battery depletion. Without an efficient system to manage charging, maintenance, and allocation, devices can quickly become a bottleneck in the workflow, leading to delays and reduced productivity. Additionally, the high turnover rates typical in these sectors can make device management even more challenging, as new employees need to be quickly trained on device usage and protocols.

Device Shrink and Loss

Device shrink—loss, theft, or misplacement of devices—is a significant concern in the warehousing and logistics sector. The large, often chaotic nature of these environments, coupled with the frequent movement of goods and equipment, makes it easy for devices to be misplaced or stolen. This issue is exacerbated by the fact that many of these devices are small, portable, and high-value, making them prime targets for theft.

The financial impact of device shrink extends beyond the cost of replacing the hardware. Lost devices often contain sensitive data, such as inventory records, shipping information, or customer details, which can be compromised if the device falls into the wrong hands. Moreover, the operational disruptions caused by missing devices can lead to delays in processing shipments, errors in inventory management, and ultimately, a decrease in customer satisfaction.

Operational Inefficiencies

In the fast-paced world of warehousing and logistics, efficiency is key. However, traditional methods of managing devices—such as manual check-in/check-out systems, unsecured storage, and ad-hoc maintenance—can create significant inefficiencies. Employees may waste valuable time searching for available devices, waiting for devices to charge, or dealing with malfunctioning equipment.

These inefficiencies can lead to a cascading effect on operations. For example, if a handheld scanner is not available when needed, it can delay the scanning of incoming or outgoing goods, disrupting the entire supply chain. Similarly, if devices are not properly maintained, they may fail during critical operations, leading to downtime and increased operational costs.

Furthermore, the lack of real-time visibility into device status and location can make it difficult for managers to allocate resources effectively, leading to imbalances in workload distribution and underutilization of available equipment. In environments where every minute counts, these inefficiencies can significantly impact the bottom line.

How ARC’s Intelligent Lockers Address These Challenges

Secure Storage and Access Control

ARC’s intelligent lockers provide a secure, centralized solution for storing mobile devices when they are not in use. These lockers are equipped with access controls such as PIN codes and RFID scanners, ensuring that only authorized personnel can retrieve or store devices. This significantly reduces the risk of theft and unauthorized use, as each device is securely stored and monitored.

The lockers also help prevent physical damage to devices by providing a safe and organized storage space, reducing the likelihood of devices being mishandled or left in unsafe environments. By securing devices when they are not in use, ARC’s lockers help maintain the integrity of the devices and ensure they are always ready for operation.

Automated Device Management

One of the key features of ARC’s intelligent lockers is their ability to automate the device management process. The lockers streamline the check-in/check-out process, automatically recording when a device is accessed, by whom, and for how long. This automation eliminates the need for manual logging and reduces the administrative burden on managers and employees.

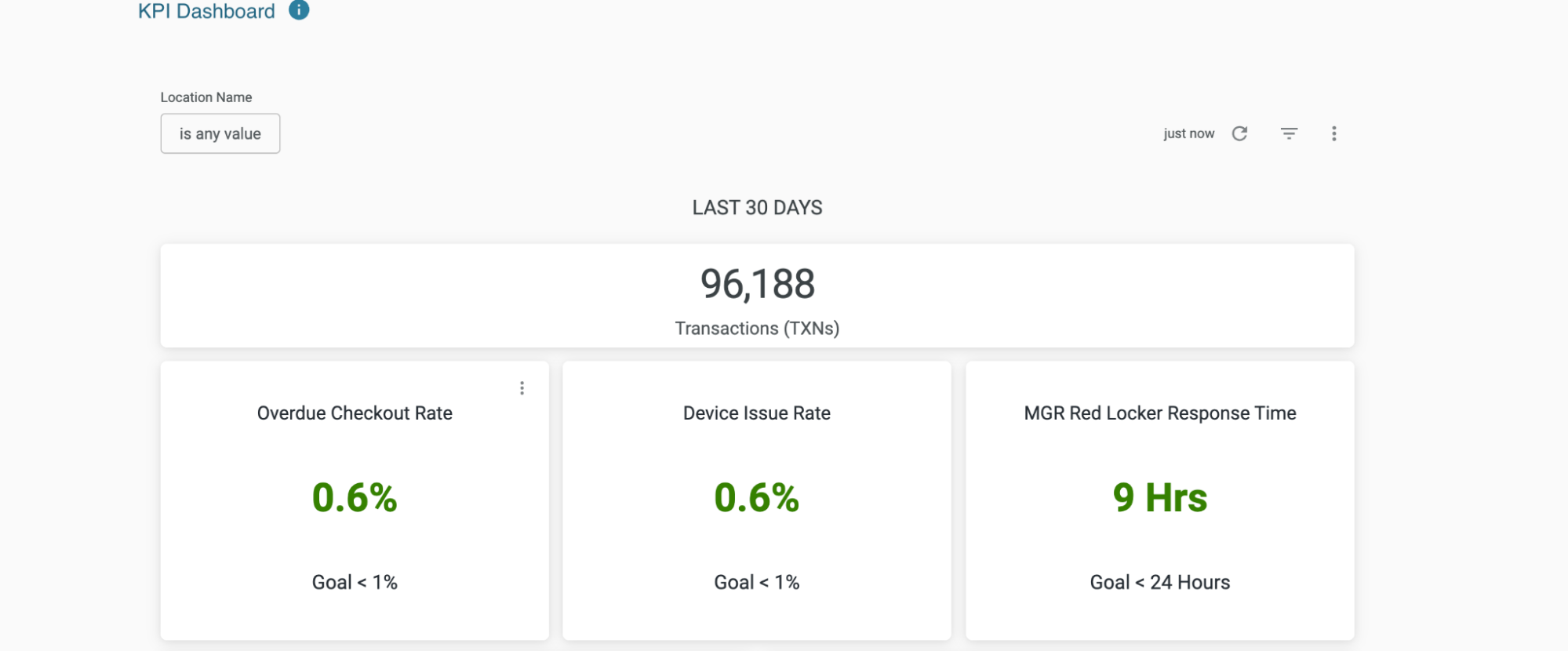

The system also provides real-time tracking of devices, allowing managers to monitor their location and status at all times. If a device is not returned on time or if there is any unusual activity, the system can send alerts to managers, enabling them to take prompt action. This real-time visibility and automation ensure that devices are always accounted for and available when needed, reducing downtime and increasing productivity.

Enhanced Accountability

ARC’s system also enhances accountability by tracking each user’s interactions with the devices. This creates a digital audit trail, holding employees accountable for the devices they use. If a device goes missing or is returned damaged, managers can quickly identify who last accessed it, making it easier to address issues and enforce accountability.

This level of accountability not only deters potential theft or misuse but also encourages employees to handle devices more carefully, knowing that their actions are being monitored. As a result, companies can reduce device shrink and ensure that devices are used responsibly and efficiently.

The Operational Impact of ARC in Warehousing and Logistics

Increased Efficiency and Productivity

The implementation of ARC’s intelligent lockers has a direct impact on the efficiency and productivity of warehousing and logistics operations. By automating the device management process and providing real-time visibility, ARC’s lockers reduce the time employees spend searching for available devices or dealing with malfunctioning equipment. This allows employees to focus on their core tasks, such as processing orders and managing inventory, without unnecessary interruptions.

The availability of fully charged and functional devices also means that employees can work more efficiently, leading to faster processing times and improved overall productivity. In an industry where speed and accuracy are critical, the benefits of having reliable access to mobile devices cannot be overstated.

Reduction in Device Shrink

ARC’s intelligent lockers have been shown to significantly reduce device shrink in warehousing and logistics environments. By providing secure storage and enforcing accountability, these lockers help prevent the loss, theft, or misplacement of devices. Companies that have implemented ARC’s solutions have reported significant reductions in device shrink, resulting in substantial cost savings and improved operational efficiency.

For example, a logistics company that deployed ARC’s intelligent lockers across its facilities saw an 85% reduction in device shrink within the first year. This not only reduced the company’s replacement costs but also minimized the operational disruptions caused by missing or malfunctioning devices.

Improved Workflow Management

The real-time data and reporting features provided by ARC’s intelligent lockers enable managers to better allocate resources and manage workflows. By having access to up-to-date information on device usage and availability, managers can ensure that devices are distributed efficiently across different teams and tasks. This improves the overall coordination of operations and helps avoid bottlenecks that can slow down processes.

In addition, the ability to monitor device performance and usage patterns allows managers to identify potential issues before they become major problems. For instance, if a particular device is frequently being reported as malfunctioning, it can be flagged for maintenance or replacement, preventing further disruptions to the workflow.

Long-Term Benefits of Implementing ARC’s Device Management Solutions

Scalability for Growing Operations

As warehousing and logistics operations grow, so does the complexity of managing an increasing number of devices. ARC’s intelligent lockers are designed to scale with the needs of the business, providing a flexible solution that can accommodate more devices and users as the company expands. This scalability ensures that the device management system remains effective and efficient, even as the demands on the system increase.

Future-Proofing Device Management

The adoption of ARC’s intelligent lockers not only addresses current challenges but also prepares warehousing and logistics companies for future demands. As technology continues to evolve and the need for efficient, secure device management grows, having a robust system in place ensures that companies are well-equipped to handle whatever challenges come their way. This future-proofing aspect makes ARC’s lockers a valuable investment for any company looking to optimize its operations and protect its assets.

ARC’s intelligent lockers have a profound impact on device management in the warehousing and logistics industry, addressing the unique challenges faced by these fast-paced environments. By providing secure storage, automating management processes, and enhancing accountability, ARC’s solutions significantly reduce device shrinkage, increase operational efficiency, and improve workflow management. For companies in the warehousing and logistics sector, implementing ARC’s intelligent lockers is a strategic decision that not only solves immediate problems but also prepares them for future growth and success.